How to Adjust Spring Loaded Hinges: Complete Professional Guide

Posted by National Lock Supply on Dec 1st 2025

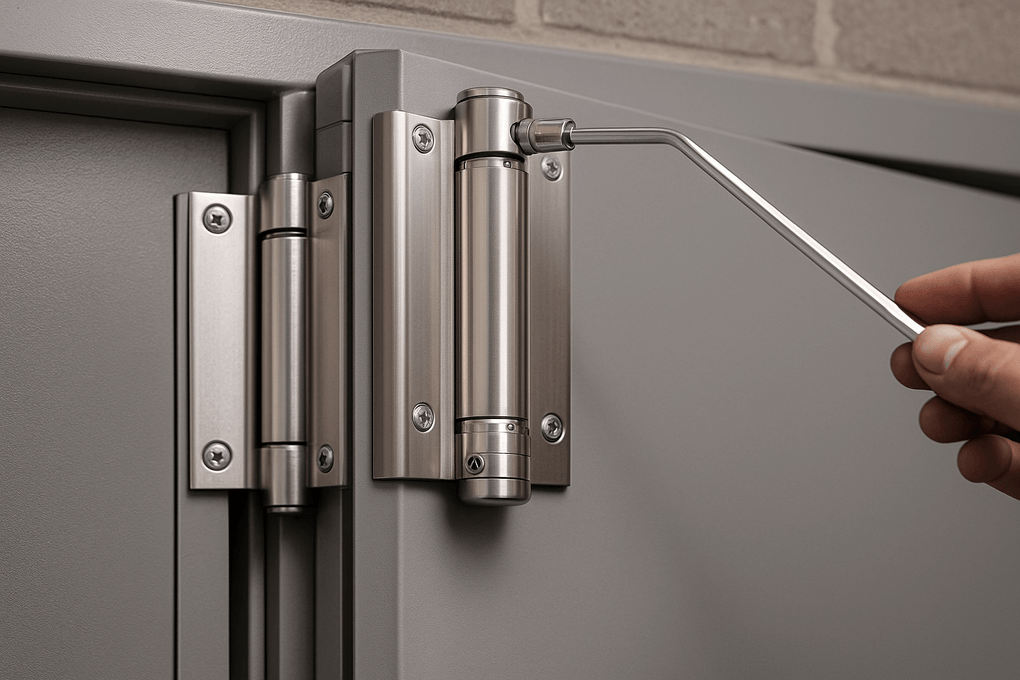

Spring loaded hinges are self-closing mechanisms that eliminate the need for door closers in many commercial applications, but their performance depends entirely on proper tension adjustment. Whether you're dealing with fire-rated stairwell doors, hotel guest room entries, or high-traffic apartment units, understanding spring hinge adjustment ensures consistent closing force, proper latching, and extended hardware lifespan.

The adjustment process requires precision and attention to detail, particularly in commercial environments where ANSI/BHMA standards and fire code requirements dictate specific closing performance. Unlike friction hinges or standard butt hinges, spring hinges contain internal torsion springs that apply controlled rotational force throughout the door's swing arc. This guide covers the technical adjustment procedures, troubleshooting methodologies, and compliance considerations that separate functional installations from code violations.

Understanding Spring Hinge Mechanics

Spring loaded hinges operate through helical torsion springs housed within the hinge barrel, applying a constant rotational force that returns the door to its closed position. The spring mechanism typically consists of coiled steel wire compressed between the hinge knuckles, with adjustment capability through a hex-key accessible tension screw located in the hinge barrel or knuckle assembly. Professional-grade spring hinges like the McKinney 1502 series and Stanley 2060R models provide tension adjustment ranges that accommodate door weights from 80 to 200 pounds, with each full rotation of the adjustment key typically adding or reducing closing force by approximately 15-20%.

The spring's effectiveness depends on several interconnected factors: door weight distribution, weatherstripping compression resistance, latch bolt throw requirements, and environmental conditions, including wind pressure or HVAC-induced pressure differentials. Standard weight spring hinges are engineered for doors up to 3'0" x 7'0" with moderate frequency use, while heavy weight configurations handle oversized or high-traffic applications. Fire-rated spring hinges must maintain UL 10C compliance, meaning adjustment procedures cannot compromise the hinge's ability to close and latch under fire conditions, a critical consideration when balancing closing speed against ADA force requirements.

Upgrade to professional-grade spring hinges with adjustable tension and UL fire ratings for reliable, code-compliant performance.

Required Tools and Safety Precautions

Proper spring hinge adjustment requires minimal but specific tools: a 3/32" or 1/8" hex key (size varies by manufacturer, always verify against the hinge specification), masking tape for marking adjustment positions, a door force gauge for measuring opening force compliance, and, optionally, a hinge pin removal tool for accessing certain adjustment mechanisms. Professional installations benefit from a torque screwdriver to prevent over-tensioning, which can strip adjustment threads or crack hinge castings in lower-grade products.

Safety protocols are non-negotiable when working with tensioned spring mechanisms. Never attempt adjustment with the door fully open beyond 90 degrees, as this position maximizes spring compression and increases the risk of sudden release. Always maintain firm control of the hex key during adjustment; spring slippage can cause the key to spin violently, resulting in hand injuries. For multiple-hinge installations, adjust hinges sequentially rather than simultaneously to maintain door control throughout the process. When working on fire-rated openings, document pre-adjustment performance to ensure modifications don't compromise the required closing force under NFPA 80 standards.

Step-by-Step Adjustment Procedure

Adjusting spring loaded hinges requires a systematic approach that balances closing force with accessibility requirements. The following procedure ensures consistent results while maintaining code compliance and preventing hardware damage. Follow each step methodically, testing door performance after every adjustment to avoid over-tensioning that can compromise both hinge longevity and user safety.

Initial Assessment

Begin by observing the door's current closing behavior through multiple complete cycles. Note the closing speed, whether the door latches consistently, and if it slams into the frame or creeps to a stop. Check for binding points in the swing arc that might indicate frame misalignment rather than spring tension issues; shimming or frame adjustment may be required before spring modification provides benefit. Measure the current opening force at the handle using a door force gauge; ADA standards require interior doors to open with 5 pounds maximum force, while exterior doors allow up to 8.5 pounds.

Locating the Adjustment Mechanism

Most commercial spring hinges feature a hex socket in the bottom barrel cap or within the hinge knuckle assembly. Remove any decorative caps or plugs to access the adjustment point. On three-knuckle spring hinges, the center barrel typically houses the spring and adjustment mechanism. Insert the correct size hex key; forcing an incorrect size will strip the socket and render the hinge non-adjustable. Mark the key's current position with tape on the door surface to track total rotation during adjustment, as most hinges provide 4-6 full rotations of adjustment range from minimum to maximum tension.

Tension Adjustment Process

To increase closing force (door closes too slowly or fails to latch), rotate the hex key clockwise in quarter-turn increments. After each quarter turn, remove the key and test the door through 3-5 complete cycles to evaluate the change. Gradual adjustment prevents over-tensioning, which can lead to excessive opening force, door slam, and premature spring fatigue. To decrease closing force (door slams or requires excessive opening force), rotate counterclockwise in the same incremental fashion.

For optimal performance, aim for door closing behavior that brings the door from 90 degrees open to approximately 3 inches from the frame in 4-6 seconds, then accelerates through the final latch engagement in 1-2 seconds. This "two-speed" closing profile ensures the door closes reliably while providing adequate time for passage. If you reach the adjustment limit (key stops turning) without achieving the desired performance, the spring hinge may be undersized for the application. Consider upgrading to heavy-weight hinges or adding additional spring hinges to distribute the closing force requirement.

Multi-Hinge Coordination

Doors equipped with multiple spring hinges require balanced adjustment across all units. Start by setting all hinges to minimum tension, then increase each hinge by equal increments (typically one-quarter turn per hinge per adjustment cycle) until the desired closing force is achieved. Unbalanced spring tension creates twisting forces that cause premature hinge bearing wear and frame distortion. On particularly heavy doors, stagger the adjustment slightly so the upper hinge provides 5-10% more closing force than lower hinges, compensating for the door's center of gravity.

SAME DAY & EXPEDITED SHIPPING AVAILABLE

SAME DAY & EXPEDITED SHIPPING AVAILABLE